General questions

|

|

|

|

|

Your name, is it Corbier or Carbier

? Your name, is it Corbier or Carbier

?

|

My name is Corbier, with an "O". The brand of the products is Carbier, with an "A".

Why ? Read the page about that. You'll know all...

|

How can I send an order ? Are credit

cards accepted ? How can I send an order ? Are credit

cards accepted ?

|

Please read the page "Orders".

Credit card payment is possible with Paypal.

|

What does mean "Price all included"

? What does mean "Price all included"

?

|

It means that the shipment costs are already in the price indicated. There is nothing to add.

|

Ignition

|

|

Hello ! I would need an electronic

ignition for my engine. What does it cost ? Hello ! I would need an electronic

ignition for my engine. What does it cost ?

|

Every week, we receive messages like this one. We can hardly answer...

For any question, we need to receive as many information as possible : vehicle brand, type (car, bike,

boat), model, type of engine (2-stroke or 4-stroke), number of coils...

|

Do you have an ignition

for to replace my volant magnétique, my magneto, my CDI ? Do you have an ignition

for to replace my volant magnétique, my magneto, my CDI ?

|

No. Carbier produces only ignition modules for engines with points-battery-coil

(so called type 1), or with inductive sensors-battery-coil (type 2).

Many use to call "CDI" all the electronic modules. The CDI are capacitive discharge ignitions.

Carbier does not work on CDI.

|

What

are the real advantages of an electronic ignition which uses

the original points ? What

are the real advantages of an electronic ignition which uses

the original points ?

|

Normally, the current flowing in the original points is about

2 to 3 A, highly inductive since it flows through the primary of the

coil. The points cut off this current several thousands of times

per minute, with an overvoltage of about 250 V every time. This

leads to arcs, to a fast wearout of the points, and to the needs

for frequent adjustments. With CARBIER, the current cut by the

points is about

40 mA, without any overvoltage. Points wearout disappears.

Only remains the wear of the part touching the cam, and this

modifies slightly the advance over the years. The ignition does

not need anymore to be adjusted frequently.

On the other hand, the fact that the condensers (which can stay

in place, but can also be removed) do not play any role makes the change rate in the

primary current of the coil extremely sharp (it is the di/dt of

the page "L'allumage

batterie-bobine"). The overvoltage at the secondary is strongly

increased, yealding in a spark of better quality. Idle becomes

more stable and can be lowered, cold cranking becomes easier,

engine resumes more strongly. The engine is very much more agreable.

This is particularly noticeable on engines with high unit displacement

(the changes on a FIAT 500 is really impressive).

|

Shall

I improve the power of my engine with an electronic ignition

? Shall

I improve the power of my engine with an electronic ignition

?

|

Accurate measurements at power bench are necessary to confirm

a power increase. But it was noted : a better behaviour when resuming power,

a more stable idle, and a slightly lower fuel consumption. Idle

may be adjusted lower. This was noted on various engines, after

A-B-A type tests. This type of test consists in making a modification,

test it, go back to the previous state, test again, and reinstall

the modification for a final test. It is a excellent way to

check a change without being abused by a first impression.

The only way to really increase the power of an engine

is to increase the torque, which means increase displacement,

and/or increase RPM. After having increased RPM by (heavy) mechanical

changes, one must improve the ignition to reach this new RPM.

This can be done by installing Carbier.

|

And the condensers ? And the condensers ?

|

The condensers of a classic ignition are connected in parallel with the points. They remove the spark

at the points when they open, and create a series of sparks at the plug instead of a unique spark. Without

condenser, it does'nt work.

With CARBIER, the consensers play no rôle accross the points. Then, according where they are in the

circuit, they can be left in place or they must be disconnected.

-

if, after installing CARBIER, the condensers are accross the points, they can be left in place.

They can be removed as well.

-

if, after installing CARBIER, the condensers are connected to the coils, they MUST be

disconnected or removed.

|

What about the centrifugal advance system

? What about the centrifugal advance system

?

|

It remains in place. Don't touch it.

|

Can CARBIER operate on an engine at

14 000 RPM ? Can CARBIER operate on an engine at

14 000 RPM ?

|

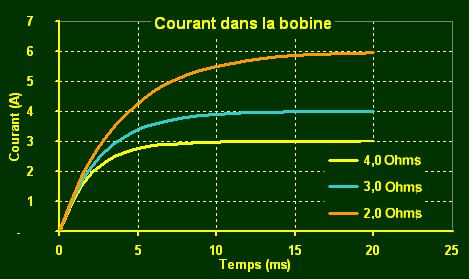

It is not CARBIER which limits the RPM of the engine, but the time needed by the current to reach its

final value in the coil. With a coil of 4 Ohms, inductance at 8 mH, it takes about 8 ms to reach a current

of 3 A under 12 Volts. This time corresponds to a rotation speed of 60 / 8 ms = 7500 RPM. Beyond this RPM,

the coil is not fully charged and the energy there stored decreases strongly (energy = 1/2 L I²). The spark

becomes weaker.

The solution to turn faster is to mount a "more powerfull" coil, which is a coil with a lower

primary resistance. Here is shown the rise time of the current in three different coils. It can be seen

that after a given time (e.g. 10 ms), the current reached is higher in a low resistance coil.

|

|

I have trimmed the advence

of my engine perfectly, and I cannot make it run above 4000 RPM. What's happening ? I have trimmed the advence

of my engine perfectly, and I cannot make it run above 4000 RPM. What's happening ?

|

Very likely, the dwell is not proprely adjusted. Please

read this text to understand the problem and correct it.

|

|

|

Why

does the life test last 1333 hours ? Why

does the life test last 1333 hours ?

|

Easy : for an engine with one spark per crankshaft turn :

life duration expected without failure : 80 000 km

average speed of the vehicle : 40 km/h. This was the average

speed of European cars some years ago. For sure, it is lower

now.

corresponding operation time : 80 000 / 40 = 2000 hours.

number of sparks during this time, assuming an RPM of 4000 min-1 : 2000 x 4000 x

60 = 480 000 000 sparks.

a test done at 3000 min-1 takes then : 2667 h or 2667 / 24 = 111 days

or 3,7 months.

to reduce the test duration, it is performed at a current

twice the nominal current. Hence the new duration : 1333 h or 56 days, or 8 weeks.

For the engines having one spark every turn of camshaft, the

test duration could be cut by two.

|

Does it work below 6 Volts ? Does it work below 6 Volts ?

|

Yes. The tests on the modules for 12 Volts show that the operation is possible

down to 4,8 Volts. Below this voltage, the spark disappears at the spark plug (on a free air test bench).

To avoid any problem under 6 Volts, some minor modifications were made to the hardware. So the version

6 Volts operates safely down to 4,0 Volts.

|

Why is there a need for a ground wire

? The bracket is attached to the frame, then to the ground. Is it not enough ? Why is there a need for a ground wire

? The bracket is attached to the frame, then to the ground. Is it not enough ?

|

The housing of the ignition Carbier and the fixation bracket are not connected to the electric circuit.

They are electrically floating. Then a wire, as short as possible, is absolutely needed to let the

coil current flow back to the ground.

|

Why not use a plastic housing for Carbier

ignition ? Why not use a plastic housing for Carbier

ignition ?

|

The housing of Carbier ignitions is made of an aluminium alloy, and serves as a heat sink for the power

transistors actuating the coils. A plastic housing could not play this rôle. The power transistors are of

a special type : they are not linked to the aluminium housing electrically, but only thermally.

|

What happens if the wire + of the Carbier

ignition is disconnected ? What happens if the wire + of the Carbier

ignition is disconnected ?

|

If the power supply wire of the Carbier ignition is disconnected, the coils go OFF. No current flows.

|

What happens if the wires + and Ground

are swapped ? What happens if the wires + and Ground

are swapped ?

|

Nothing. It does not work. When wired correctly, it starts again.

|

What happens if the input wires and

output wires are swapped ? What happens if the input wires and

output wires are swapped ?

|

Nothing. It does not work. When wired correctly, it starts again.

|

|

|

|